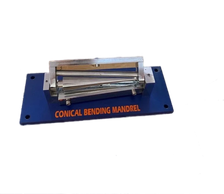

Conical Bending Mandrel

Conical Bending Mandrel

It is laboratory equipment used to bend coated test panels to assess the elasticity over a conical-shaped mandrel, or varnish to cracking, or resistance of coating paint, detachment from metal test panel and elongation. The bending area’s conical shape allows test panel deformation and also examines the coating elasticity range. For tabletop use, the Conical Bending Mandrel Tester is a compact equipment made of enameled steel. The pivoted pressure running roller and Conical Mandrel are made of stainless steel. The clamping device consists of a cam lever that ensures speedy and complicated changes in the sample.

Model ELI- CBM

The Bending Mandrel Test is mostly used to test the flexibility and adhesive properties of the coating when these are subjected to bending force.

Paints are used for a variety of functions, including ( metal corrosion protection, thermal insulation to reduce the energy consumption of cooling devices, fire-resistant coatings, hiding gaps in a wall) improving the appearance of automobiles and so on. The essential characteristics of good paint are its longevity, durability, and colour fastness. The Conical Mandrel Tending tester is used to detect the greatest cone diameter at which (flaking and cracking) occur after bending. The paint quality is assessed by bending a metal substrate that has been painted to a certain angle. The tool ( Conical Mandrel tester’s) primary function is to determine the coating’s properties and resistance to cracking from the substrate. This is a typical method for evaluating coating flexibility and adherence when subjected to bending force. The Conical Mandrel Bend Tester is used for the analysis of coating qualities by bending the test material, for example; a coated plate, around a conically formed metal bar.

Conical bending machine design:

A Conical Mandrel Bending Tester consists of the controller, base plate, eccentric sample locking lever, footrest, conical rod, and movement lever that comprise the instrument. The conical rod measures 8 inches long and has a diameter ranging from 3.2 mm to 38.1mm. A 2mm thickness sample can be measured. The tester body is made of mild steel chrome plated. The testing technique is purely manual and easy.

| Conical Cylinder | Diameter of Conical Cylinder 3.1mm ±0.1mm and 38 mm ±0.1 mm |

| Length of Conical Cylinder | 8 Inch |

| Max Sample Thickness | 0.8 mm |

| Sample Clamp | Hand Operated Lever |

| Conical Cylinder Material | Stainless Steel |

| As per Sample size | 75 mm x 150 mm |

| Measuring Scale | 1 (Inbuilt in Machine) |

| Steel Roller | 1 (Inbuilt in Machine) |

| Material / Finish | Mild Steel Bright Chrome Plated for corrosion Resistant finish |

• Effective Conical Bending Mandrel is a laboratory apparatus to bend coated test panels over a conical shaped mandrel in

order to assess the elasticity or resistance of a coating paint or varnish to cracking; elongation and / or detachment from

a metal test panel in accordance with ISO 6860 and ASTM D522.

• The conical shape of the bending area allows the deformation of the test panel and examination of the elasticity range

of a coating.

• Bending mandrel with multiple mandrel size also available on request.

Get in Touch

Working of Conical mandrel bend tester

- Turn the bending lever towards the clamp until it stops, then insert the test sheet with the coated side outward into the clamping device between the cone and pressure roller.

- Push the locking lever at the smaller end of the cone and secure the sample with the same lever. Insert a layer of sheet between the sample and pressure roller to protect the sensitive paint surfaces.

- Turn the bending lever for about 2-3 seconds smoothly around the mandrel to bend the sample and inspect for cracks.

After completing the testing procedures, examine the sample to determine the degree of any cracks or scratches in the paint. This is a tabletop instrument that is simple to set up and requires little maintenance.

Our Related Products

Salt Spray Chamber Jupiter Series

Cyclic corrosion Salt Spray Chamber

Hot Water Bath- Digital

CASS Cum Salt Spray Chamber

Xenon Arc Test Chambers

Fume Hood

Uv weathering accelerated tester

Ozone Test Chamber

Humidity Test Chamber