How to Conduct a Salt Spray Test and Salt Spray Test Procedure

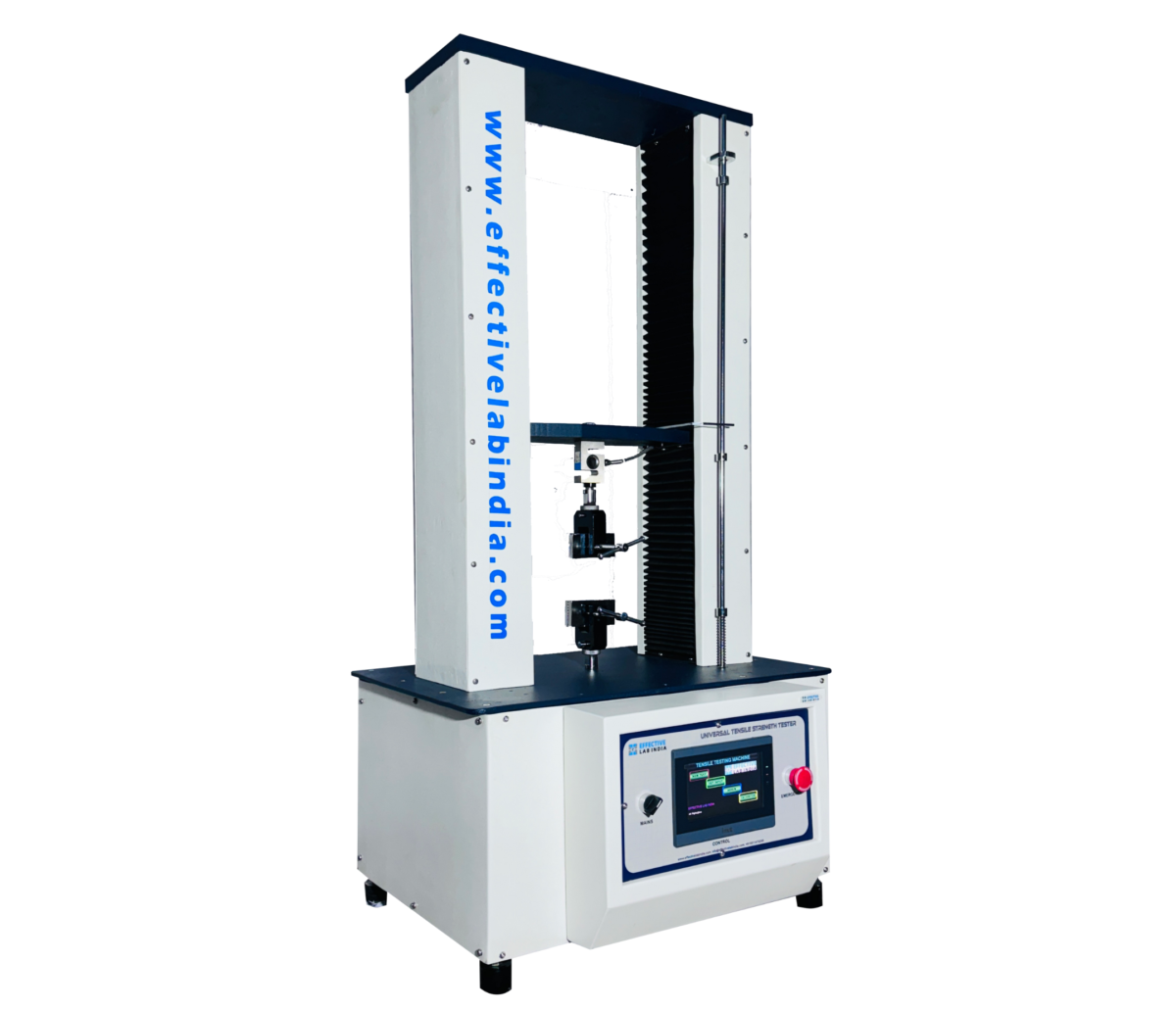

February 28, 2025A universal tensile testing machine (UTM) is a versatile laboratory equipment used to evaluate the mechanical properties of the material, such as tensile strength, compression, bending, modulus and elongation. The UTM machine is widely used in industries such as Construction, Plastic Manufacturing, Paper and Pulp, Rubber Industry, Automotive Industry and Research, and is necessary for quality control and material testing. In this guide, we will drive you through a step-by-step process with the operation of a universal tensile test machine, while explaining its functional theory and main features.

What is a Universal Tensile Testing Machine?

A universal test machine, often referred to as a UTM machine or universal tensile strength tester, is designed to use controlled forces on a material until it does not distort or fracture. It provides valuable machine analysis data and measurement of the reaction of the material to stress and strain. The ability to test multiple tests makes it a universal tool for material testing.

Universal Tensile Testing Machine Working Principle

The working principle of the UTM machine is based on applying a tensile or compressed force on the sample and measuring its deformation. Here’s how it works:

- Load application: The machine uses a hydraulic or electromechanical system to use a controlled force on the material.

- Deformation measurement: When the force is applied by the machine, the material is spread or compressed. The machine records changes in length, shape or size.

- Data collection: Sensors and software capture data on stress (force per unit area) and stress (relative deformation of the original size).

- Analysis: Data is used to produce stress-strain curves, which help determine the mechanical properties of the material.

Step-by-Step Guide to Operating a Universal Tensile Testing Machine

Step 1: Preparation

- Select the Right Fixtures: Select the right grip, jaw or fixtures depending on the type of material and type of testing (stretch, compression, etc.).

- Calibrate the Machine: Make sure the UTM testing machine is calibrated following the manufacturer’s guidelines to ensure accurate results.

- Prepare the Specimen: Cut or shape the material in the required dimensions according to the test standards (eg ASTM or ISO).

Step 2: Mounting the Specimen

- Secure the Specimen: Place the material in the grips or fixtures, ensuring it is properly aligned and centred.

- Tighten the Grips: To avoid slippings during testing, use machine control to tighten the grips safely.

Step 3: Setting Up the Software

- Open the Testing Software: Start the software associated with Universal Tensile Strength tests.

- Input Test Parameters: Enter details like specimen dimensions, test type, and desired speed of force application.

- Zero the Machine: Reset the load and offset reading to zero to ensure accurate measurement.

Step 4: Running the Test

- Start the Test: Start the test with a software or control panel. The machine will start using power for samples.

- Monitor the Process: Real-time inspection to ensure that the sample is deforming as expected and that the machine works properly.

- Stop the Test: The test stops automatically after reaching the sample break or a predetermined limit.

Step 5: Analyzing Results

- Review Data: The software will show a stress-strain curve and other relevant data.

- Calculate Properties: Determine key properties such as tensile strength, yield strength and elongation at break.

- Generate Reports: Save or print the test results for further analysis or documentation.

Step 6: Post-Test Maintenance

- Clean the Grips: Remove everything debris or remains to be ready for the next test.

- Inspect the Machine: Check for any signs of wear or damage and perform routine maintenance as needed.

Tips for Effective Use of a UTM Machine

- Always follow the manufacturer’s operating and maintenance guidelines.

- Use proper fixtures and grips to avoid damage to the sample or machine.

- Calibrates the usual universal tensile strength tester to maintain accuracy.

- Keep the test environment clean and free of vibration or disruption.

Applications of a Universal Testing Machine

- Construction: Testing the strength of concrete, steel and other structural materials.

- Production: Evaluation of quality of metals, plastic and composite.

- Research: Study of mechanical properties for new materials.

- Quality control: Secure products meet industry standards and specifications.

The Primary Objectives:

The operation of a universal tensile testing machine may seem complex at first, but by following this step-by-step guide, you can testify effectively and get accurate results. Understanding the working principle and its applications of the universal tensile strength tester will help you take the maximum benefit from this powerful equipment. Whether you test metals, plastic or composites, a UTM machine is an indispensable feature to ensure the quality and performance of the material.

By mastering the operation of a universal tensile test machine, you can increase the test processes, improve product quality and fulfil industry standards with confidence.