Universal Tensile Testing Machines

Effective Lab India is one of the top manufacturers of universal testing machines. For the past 10 years, they have been making high-quality equipment and offering a large choice of universal testing machines that can test many different materials. Universal Testing Machine (UTM), is the most important testing equipment, also known as Tensile Testing Machine, is a type of equipment used to test various types of metals on raw materials and various components by the machine/tester. It can be used to test materials for tensile strength, compressive strength, flexural strength and shear strength. It is very important for quality control, research and development in various industries.

Read more

UTM Machine/Tester is important for quality control and assurance in many industries, as it can help to test the durability of the materials against Universal forces. With user-friendly software integration and advanced testing capabilities, the results you obtain are not only reliable but also ready for deep analysis. Trust in the precision that enhances your research. Engineered with the finest components, the Universal Testing Machines from Effective Lab India are built to last.

Tensile Testing – To ensure the pulling of material, how much forces are applied on it so that it can stretch before breaking.

Compression testing – Crushing a material and applying force to it to see how it behaves under the crushing force

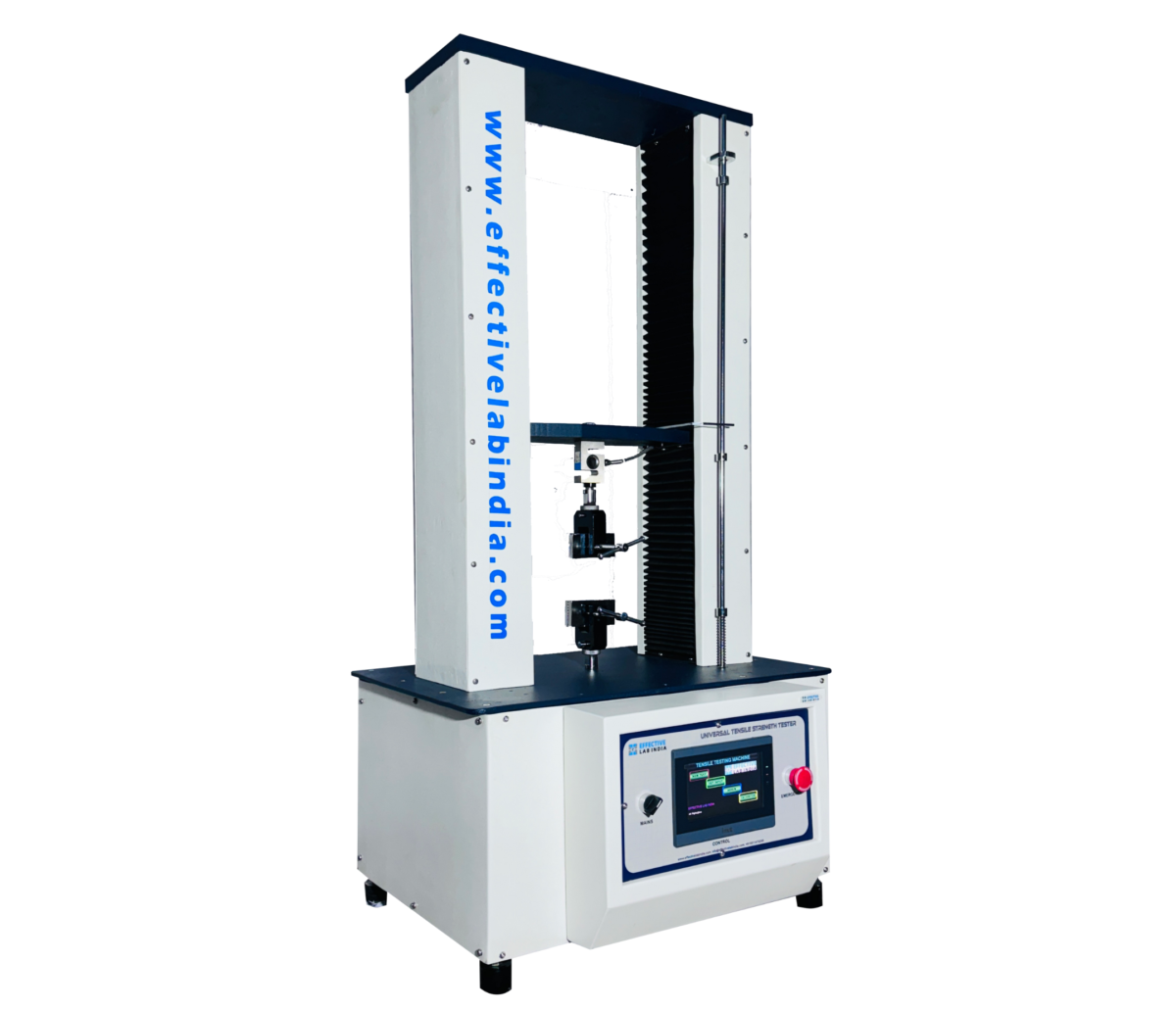

Universal Tensile Strength Tester

Accurate and reliable tensile testing for strong, durable materials

What is a Universal Tensile Testing Machine (UTM)?

When it comes to testing the strength, product standard and durability of the material, Universal Tensile Test Machine (UTM) plays a necessary role in quality control laboratories, R&D processes and manufacturing industries worldwide. Effective Lab India UTM Machine has a strong, robust design, a user-friendly digital control panel and upgraded sensors, making it a versatile mechanical testing tool used to evaluate tensile force, compression strength, elongation, yield point and other mechanical properties of materials. This machine works by using controlled mechanical tension or compression strength for a sample until it breaks, and provides accurate data on its physical behaviour under stress.

Key Features of Effective Lab India UTM

- High Precision Load Cells: Provide very accurate strength measurement, important for reliable results.

- Exact Crosshead movement: Offers the controlled, smooth and continuous test speed of advanced motor systems (often servo-motor).

- User-friendly software: Windows-based software with easy setup, real-time data visualisation (stress-load curves), data collection, analysis and report generation.

- Versatile grip and fixtures: An interchangeable grip and fixtures are available to adjust to different types of material, shapes and test standards.

- Overload and Overtravel Protection: Underlying safety facilities to protect both the operator and the machine from damage.

- Convertible speed control: Allows customised testing at different crosshead speeds according to material and specific research requirements.

- Auto-Return feature: After a test, the machine can automatically return to its original position, saving time and effort.

- Compliance with Standards: Designed to follow international test standards such as ASTM D638, ISO 527, EN and BIS.

Technical Specifications

- Load Capacity: 100 kgf to 5000 kgf range

- Display: Digital LCD with backlighting and RS232 Port PC interface.

- Motor: High-quality induction motors (3 hp, Crompton/Bharat Bijlee make) with gearbox, often with Variable Frequency Drives (VFD) for precise speed control. Sarvo motor options are also available.

- Cross Head Speed: Usually with high-resolution speed setting, 40 mm/min to 400 mm/min or more.

- Force Measurement Accuracy: Often ±0.5% of Full Scale Deflection (FSD) or better.

- Crosshead Displacement Resolution: High resolution, e.g. 0.01 mm to 1 mm, based on model.

- Load Sensor: S Type

- Grip to Grip Travel Length: Varies by model, typically 60mm – 850mm

- Safety Features: Limit switches for over-travel protection, overload protection.

- Construction material: Mild Steel, Powder Coated, with stiff lead screws for smooth movement.

- Power supply: Usually 220V AC, single phase, 50 Hz.

- Speed Drive: Available in Crompton/ Delta make

UTM Machine Applications

Effective Lab India's Universal Tensile Testing Machine is used in many industrial and research areas, mainly including:

- Metal and alloys: Determination of the elasticity module for tensile strength, yield force, testing bars, elongation and elasticity for steel, aluminium, copper, etc.

- Plastic and polymer: Testing tension, elongation at break, tear resistance and bending properties for various plastic products, films and packaging.

- Textiles and Fabrics: to assess tensile strength, tear strength, seam force and fabrics, yarns and garments, stretches, industrial fabrics and protective clothing.

- Rubber and elastomers: Accessing the tensile strength, elongation and tear resistance of rubber, seals, tires and other elastic applications.

- Composite: To evaluate the strength and behaviour of multiple types of materials used in aerospace, sports equipment and other applications.

- Adhesives and Fasteners: Fasteners testing of pull-out strength and adhesive peel bond strength.

- Concrete and Ceramics: For compression and bending testing to determine mainly strength and integrity.

- Paper and packaging: Test paperboard, corrugated boxes, tape and adhesives tests for tensile, peel and puncture resistance.

How does a UTM work?

UTMS work theory includes:

- Fix the sample between the upper and lower grip.

- Set test parameters on controls or software.

- Applying force at a controlled speed to the sample breaks.

- Measure maximum load, elongation, return(yield) point, brake point and other parameters.

- To generate detailed graphs as a curve graph for analysis.

Manufacturer and Price Details

Effective Lab India is a leading manufacturer and exporter of Universal Tensile Strength Testing Machines (UTM) in India. Our instrument is built with a robust machine design for long-lasting performance, a customised solutioncompetitive price, and international testing standards. Our UTMs are widely used in R&D labs, quality control departments, academic institutions, and third-party testing research labs across India.

The price of a universal tensile test machine from Effective Lab India can range from ₹65,000 to ₹ 5.50,000. More importantly, based on the load capacity, features (computerised model, digital display, HMI touch screen, servo or AC motor) and specific accessories.

Conclusion:

Universal Testing Machine is the most useful versatile and essential equipment testing laboratory equipment tool used to test the mechanical properties of various materials under tensile, compression, bending and shear loads. Effective Lab India Universal Testing Machine plays a vital role in this way as they perform multiple activities to protect the material and ensure safety, durability and reliability in engineering applications. They provide accurate measurements of key mechanical properties such as tensile strength, compressive strength, yield strength, elongation and modulus of elasticity. So, if you want to buy this Universal Testing Machine (UTM) then you are at the right place from where you can buy our Universal Testing Machine at affordable rates. We are one of the best Universal Testing Machine manufacturers, exporters and suppliers available in India to meet your requirements.

| Minimum Order Quantity | 1 Piece |

| Brand | ELI |

| Capacity | 1-5 TON |

| Model Name/Number | UTES-100 |

| Material | Mild Steel, Ball Screw |

| Display Type | HMI, Motor - Servo |

| Power | 3 PHASE |

- Versatility – Can perform multiple types of tests on a variety of materials.

- Accuracy – Provides precise measurements of mechanical properties, ensuring that materials meet specific standards.

- Efficiency – Automated and computer-controlled machines improve testing speed and reduce the chances of human error.

- Data Collection – Advanced UTMs can generate detailed reports and graphs, allowing engineers to analyze results for quality control or product development.

Know About Our Products

Universal Testing Machines (UTMs) are indispensable tools for industries involved in material testing. These machines are designed to evaluate the tensile strength, compression resistance, and flexure performance of various materials, making them vital in ensuring product reliability and safety.

The Universal Testing Machine is a unique versatile instrument used to test the mechanical properties of materials including their tensile, compression and flexural (bending) strength. It is also known by the name "Universal" because of its functionality to be used for a variety of mechanical tests on a wide range of materials such as metals, plastics, rubber, wood and composites.

Universal Testing Machines are known as versatile material testing equipment's which are used for testing a wide range of materials including metals, plastics, composites, and textiles. With the help of this testing machine, we can determine the mechanical properties such as tensile strength, compressive strength, elongation, flexural strength, and more.

Universal Testing Machine (UTM) ensures the quality of materials by testing to measure the mechanical properties of materials and components under controlled conditions. This happens when various types of controlled forces (such as pulling, pushing or bending) are applied on it. It plays an important role in quality control, product development and standards compliance.

Yes, Universal Testing Machines are considered to be cost effective, there are many reasons that make them stand out like their versatile testing capabilities, low material wastage and ability to have multiple functionalities in one machine.

Contact Form

Connect with us will help you with their queries...

For accurate laboratory testing results? contact us

for high-quality testing equipment solutions.