How to Calculate Box Compression Strength of Corrugated Box

February 18, 2025

Comparing Salt Spray Test Methods: NSS, AASS, and CASS

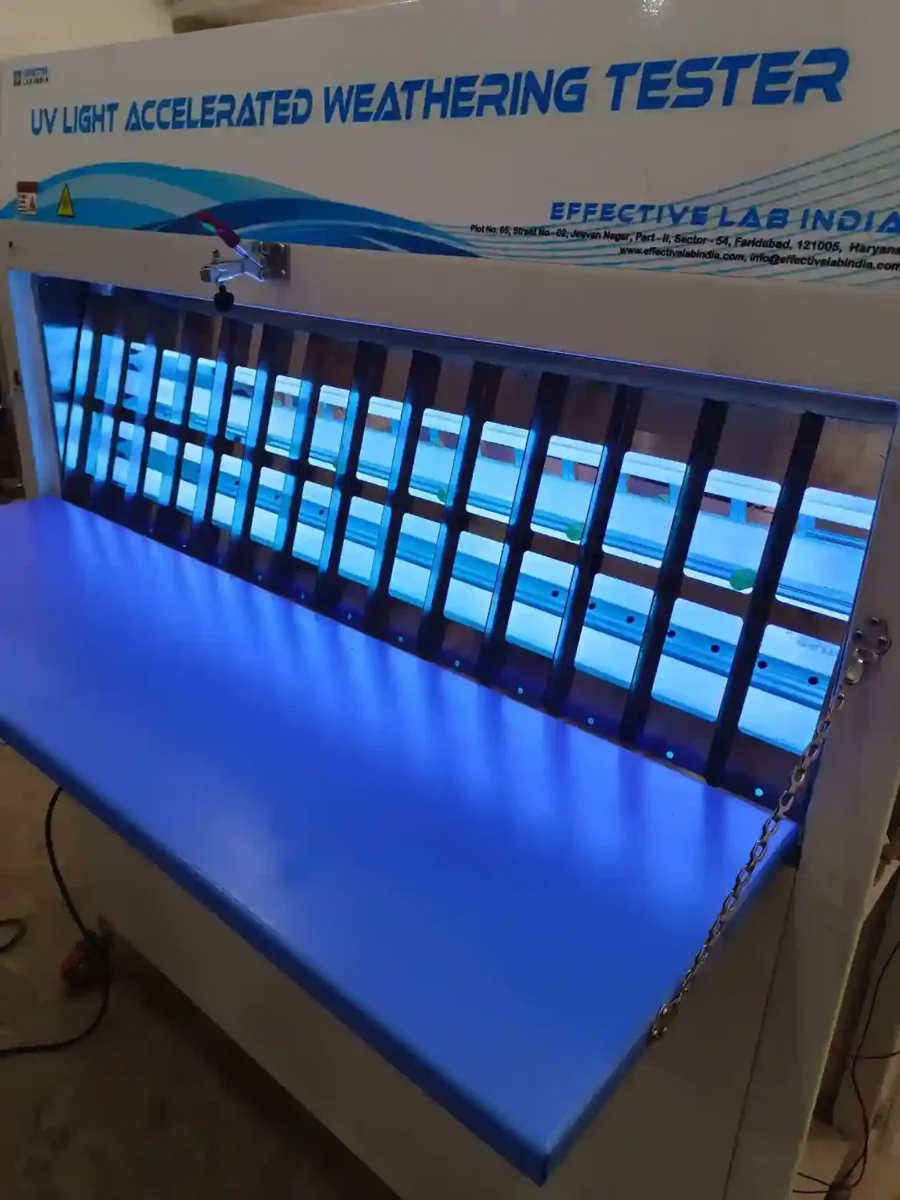

February 21, 2025In today’s competitive production world, it is more important than ever to ensure that products can withstand environmental factors about the test of time. An important tool for this test is a UV light accelerated weathering tester. This UV chamber simulates the effect of sunlight, rain and dew to predict the durability of materials that come into contact with the external environment. Let’s examine the operation of this testing instrument’s amazing technology works!!

What is a UV Light Accelerated Weathering Tester?

A UV light accelerated weathering chamber is a special test tool designed to reproduce the harmful effects of UV radiation, temperature and humidity in a controlled environment. By exposing the material to this simulated weathering, manufacturers can identify weaknesses and make improvements to enhance longevity.

This test method is usually used in industries such as motor vehicles, coatings, plastic, textiles and construction. The results help companies ensure that their products resist fading, hoof, peeling and other forms of decline.

Working Principle of UV Light Accelerated Weathering Tester

A UV accelerated weathering tester operates based on simulating the main environmental elements that lead to material deterioration. Let’s dissect the main elements of this procedure:

- UV Light Exposure:

- The chamber uses fluorescent UV lamps to simulate sunlight. These lamps usually emit UVA or UVB wavelength, which are responsible for most polymer decreases.

- By controlling the intensity and duration of UV exposure, the test provides speed to the aging process, which gives results for days or weeks instead of months or years.

- Temperature Control:

- The chamber maintains an accurate temperature level to simulate heat and moist external conditions.

- High temperatures accelerate chemical reactions that cause fracture of the material and provide more extensive evaluation.

- Moisture Simulation:

- The examiner introduces moisture through water spray, condensation or moisture control, mimics dew and rainy cycles.

- These cycles stress materials, revealing issues such as blisters, cracks and corrosion.

- Cycle Repetition:

- The machine alternates between UV exposure and moisture condensation, which leads to a repetitive cycle that simulates the pattern during the day and night weather season.

- This continuous stress test provides reliable insight into long-term material performance.

How to Accelerate UV Testing

Accelerated UV testing is an important part of quality control and research and development in many industries. Let’s find out how we do this test effectively.

- Sample Preparation:

- Cut or size test samples to fit inside the UV weathering test chamber.

- Clean samples to remove contaminated material that can affect the results.

- Setting Test Parameters:

- Select the UV wavelength (UVA or UVB) that is suitable for the material and test requirements.

- Modify the length of time that the moisture condensation and UV light exposure cycles occur.

- Set the temperature and humidity level to be consistent with the projected circumstances.

- Testing Cycle:

- Place the samples in the UV chamber and start the test.

- Monitor the internal conditions in the chamber to ensure frequent exposure.

- Observation and Data Collection:

- Investigate signs of discolouration, cracks, glossy losses and mechanical degradation from time to time.

- Carefully record all the observations, as small changes can also indicate significant physical weaknesses.

- Analysis and Reporting:

- Compare tested samples with unexposed controls.

- Create a detailed report that emphasizes the resistance of the material to UV damage.

Benefits of Using a UV Light Accelerated Weathering Tester

- Quick results: Identify potential problems for weeks instead of waiting years for natural weathering.

- Cost effects: Avoid expensive product failures by quickly catching problems in development.

- Standardized tests: Ensure international quality standards.

- Product improvement: Get insight to increase material formulations and coating.

Uv Weathering Test Procedure

The UV weathering test procedure usually follows international standards such as ASTM G154 or ISO 4892-3. These standards specify the type of UV lamp cycle durations and moisture methods, which ensure frequent and reliable results across industries.

International Quality Standards for UV Light Weathering Chambers

To ensure accurate and reliable testing, UV light weather chambers must follow internationally recognized quality standards. Some of the key standards include:

- ASTM G154:

- Standard exercises for operating fluorescent UV lamps for contact with non-metal materials.

- The test defines the cycle, lamp type and exposure position.

- ASTM G151:

- Standard exercises to highlight non-metal materials in quick testing units when using laboratory light sources.

- Provides guidelines for equipment setup and sample exposure.

- ISO 4892-1 to ISO 4892-3:

- The laboratory specifies methods for exposure to light sources.

- Covers UV fluorescent lamp exposure, temperature control, and humidity regulation.

- EN 927-6:

- A European standard for evaluating coatings on wood products during UV and moisture risk.

- ISO 11341:

- Focuses on paints and varnishes, detailing accelerated weathering tests with UV radiation and water.

- JIS K 5600-7-7:

- A Japanese industrial standard outlining weathering testing methods for coatings and paints.

Compliance with these standards ensures that the results of UV weathering tests are accurate, repetitive and comparable to different laboratories and industries.

UV Light Accelerated Weathering Tester Price.

The UV light accelerated weathering tester price can vary significantly based on the size of the chamber, the type of lamp used, the control systems, and whether or not certain testing standards are met. Any testing facility would benefit from investing in a high-quality model since it guarantees precise, consistent findings.

Final Thoughts

Knowing how a UV light accelerated weathering tester operates enables manufacturers to make products that can withstand harsh environmental conditions. This crucial piece of testing equipment offers the information required to guarantee performance and durability, from UV exposure to moisture cycles. Including UV testing in your quality control procedure is a wise move for long-term success, regardless of whether you manufacture outdoor equipment or work in the coatings sector.

For additional information about locating the ideal UV weathering chamber for your needs, don’t be afraid to get in touch with reputable manufacturers like Effective Lab India. Let’s keep your products shining bright, rain or glowing!