Vacuum Leak Tester: How to Use, Working, Features, Specification, and Manufacturer

February 25, 2025

What is an Edge Crush Tester and What is Its Use?

March 20, 2025In today’s competitive market, it is necessary to ensure the durability of material and corrosion resistance. One of the most effective ways to test a material’s resistance to rust and corrosion is a salt spray test. Whether you are a manufacturer, professional quality control or just interested in material testing, this guide will run through a simple and easy way throughout the entire salt spray test procedure.

What is a Salt Spray Test?

A salty spray test (also called a salt fog test) is a standardised corrosion test used to check how coatings and materials can withstand a harsh or corrosive environment. This test helps industries secure their products for a long time and maintain the quality under real conditions.

Industries such as the automotive industry, aerospace, marine and construction use this test to evaluate paint, coating and metal finish.

Why is the Salt Spray Test Important?

- Predicts corrosion resistance of metals and coating

- Product for use over a long time ensures shelf life

- Helps manufacturers improve coatings before launching products

- ASTM B117, ISO 9227, and JIS Z 2371 meet industry standards

If you manufacture or use metal parts, this test is an important step to ensure quality and long life.

Salt Spray Test Procedure

Performing a salt spray test involves a series of carefully controlled steps. Let’s go through them one by one:

Step 1: Prepare the Test Specimen

Before starting the test, make sure your specimen (the material or coated sample) is:

- Clean and free from oil or dirt

- Properly labelled for identification

- Prepared according to the standard test specifications

Step 2: Prepare the Salt Solution

The test requires a 5% sodium chloride (NaCl) solution in deionized or distilled water. The pH level should be between 6.5 and 7.2.

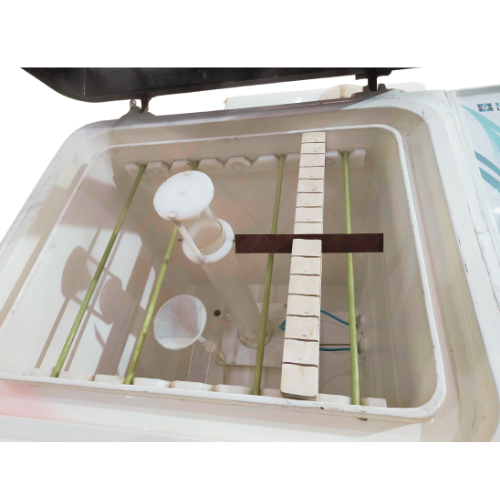

Step 3: Set Up the Salt Spray Chamber

A salt spray chamber (corrosion test chamber) is used to create a controlled environment. Make sure:

- The temperature is set to 35 °C (95 °F)

- The room is properly sealed to prevent leaks

- Spray nozzles work properly for steady fog distribution

Step 4: Start the Test

Everything is clear once:

- Keep samples inside the chamber for a 15° to 30° angle

- Turn the chamber and let salted fog spread

- Keep a constant exposure of a specific time (e.g., 24, 48, 96 or 500+ hours) depending on the test standard.

Step 5: Monitor the test status

During the test, check:

- PH of the overall solution

- Air pressure and spray distribution

- Temperature and humidity level

Step 6: Complete the test and inspect the samples

When the duration of the test is completed:

- Remove the samples carefully

- Rinse with degenerate water (to prevent corrosion reaction)

- Let them dry before inspection

Step 7: Evaluate the Results

Check for:

- Rust formation or corrosion spots

- Blistering, peeling, or discoloration

- Adhesion failure of coatings

To determine the results with industry standards to compare whether the material passes or fails.

How Long Does a Salt Spray Test Take?

The duration varies based on the material and test standard:

- 24-48 hours – for basic corrosion resistance

- 96–500 hours – for industrial coating and automotive parts

- 1000+ hours – high demonstrations for coatings and marine applications

Standards for Salt Spray Testing

Many international standards are followed by our salt spray test chamber to define the salt spray test procedure, including:

- ASTM B117 – Salt Fog is mostly used for testing

- ISO 9227 – International Standards for Rust Resistance Test

- JIS Z 2371 – Japanese industrial standards for salt spray tests

Always follow the current standard for accurate and reliable results.

Common Applications of Salt Spray Testing

- Automotive – Checking corrosion resistance for car parts and coatings

- Marine Industry – Ensure the durability of ship components

- Aerospace – Testing aircraft materials against corrosion

- Construction – Evaluation of metal structures and coatings

- Electronics – Ensure a long life for electrical enclosures

Conclusion

The salt spray test is a powerful and widely used method for assessing corrosion resistance in different materials. By following the correct salt spray testing procedure, the industry can improve product quality and durability.

In Effective Lab India, we specialize in accurate and reliable salt spray test services. If you need a professional test, feel free to contact us today!

📞 Call us: +91 9555515525

📩 Email: info@effectivelabindia.com

🌐 Visit our Website: www.effectivelabindia.com

Let’s ensure your products stand the test of time!