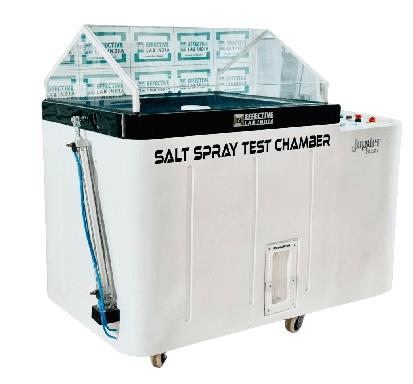

Salt Spray Test Chamber

Effective Lab India Salt Spray Test Chamber is designed to assess the corrosion resistance of coatings and metals, including paints, powder coatings, and platings like zinc, nickel, and chrome. Adhering to ASTM B117, ISO 9227, JIS Z 2371, and ASTM G85 standards, it creates a controlled, salty environment using a solution of 95% DM water and 5% NACL. Constructed from corrosion-resistant materials such as fibreglass-reinforced plastic (FRP) or stainless steel, it ensures durability and accurate, reliable testing results. Ideal for industries like automotive, aerospace, and marine, it provides essential insights into the longevity and performance of coatings and platings.

A Salt Spray Test Chamber is a specialized piece of equipment used to simulate corrosion over a short period of time. The test involves spraying a fine mist of a salt solution onto the product, exposing it to conditions that mimic long-term exposure to saltwater or saline environments. The purpose of this testing is to assess how materials, especially metals and coatings, hold up against corrosion over time.

Salt Spray Test Chamber Suppliers

Effective Lab India Salt Spray Testing, also known as the Salt Fog Test, is an accelerated corrosion test used to evaluate the corrosion resistance of metallic materials, surface coatings, platings, paints, and finishes. The test simulates a marine or coastal environment by exposing samples to a fine mist of salt solution under controlled conditions.The test exposes specimens to a continuous spray of salt-laden mist inside a closed chamber.

The salt solution (usually sodium chloride in deionized water) creates a highly corrosive environment, accelerating oxidation and corrosion reactions.Salt Spray Testing is a standard accelerated corrosion test used worldwide for quality control and material comparison. While it is not a true life-prediction tool, it remains a valuable method for assessing the durability of coatings and finishes under corrosive environments.

Built to Withstand, Tested to Last

Ensure long-lasting protection with our Salt Spray Test Chamber, delivering reliable corrosion resistance

What is a Salt Spray Test Chamber?

A Salt Spray Test Chamber is a specialized piece of equipment used to simulate corrosion over a short period of time. The test involves spraying a fine mist of a salt solution onto the product, exposing it to conditions that mimic long-term exposure to saltwater or saline environments. The purpose of this testing is to assess how materials, especially metals and coatings, hold up against corrosion over time.

How does a salt spray chamber work?

Using the Corrosion Test Chamber is very simple, so even beginners can easily perform complex tests. Just follow these steps for the best results:

- Preparation: Begin by preparing the test samples according to the specific requirements of your industry standards. Ensure they are clean and free from any contaminants.

- Loading Samples: PCarefully place the samples inside the chamber, ensuring they do not touch each other or the chamber walls to avoid cross-contamination.

- Setting Parameters:Program the chamber with the required parameters such as temperature, humidity, and duration of the test. These parameters are crucial and should be set according to the standards you are adhering to.

- Starting the Test:Initiate the test cycle. The chamber will spray a fine mist of salt solution, simulating a corrosive environment.

- Monitoring:Regularly monitor the progress through the observation window or digital display. Ensure the chamber maintains consistent conditions throughout the test.

- Post-Test Analysis: Once the test is complete, remove the samples and analyze them for signs of corrosion.

What is the Salt Spray Chamber Price in India?

The pricing of the salt spray chamber varies differently. There are several manufacturers which offer several prices for this instrument. This price ranges from country to country. In every country, the price should be different. The typical price of Salt Spray Test Chamber in India ranges from around ₹ 70,000 Thousands to ₹ 8,00000 Lakh.

Conclusion

Salt spray test machines are an essential tool for ensuring the durability and reliability of products across numerous industries. Effective Lab India, with its cutting-edge technology, expertise, and customer-focused approach, stands out as a leading manufacturer in India, offering solutions that meet both standard and specialized testing requirements.

| Chamber Temperature Range | Ambient to 40°C |

|---|---|

| Power | 220V, Single phase, 50Hz, 15 A |

| Test Air Pressure | 0.7kg/cm²-1.2kg/cm² |

| Test Chamber Temperature Range | 35°C ± 2°C |

| Chamber Temperature List Count | 0.1°C |

| Temperature Control | Inbuilt PID Temperature Controller |

| pH value of Salt Solution | 6.5 to 7.2 pH |

| Air Saturator Temperature Least Count | 0.1ºC |

| Air Saturator Temperature Repeatability | ± 2ºC |

| Available Size | Models |

| 1 | Digital - 250 |

| 2 | Digital - 300 |

| 3 | Digital - 450 |

| 4 | Digital - 1000 |

| Inner Dimensions (mm) | Outer Dimensions (mm) |

| 780mmX620mmX720mm | 1540mmx1070mmx1300mm |

| 800mmx570mmx700mm | 1600mmx280mmx1350mm |

| 950mmx700mmx720mm | 1800mmx1250mmx1250mm |

| 1600mmx800mmx800mm | 2500mmx1200mmx1550mm |

- Various grades of metal can be easily tested.

- For an effective mode of operation, digital controls are provided.

- The results of testing are highly accurate.

- It is structured with strong rigged material for effective testing.

- Data management is easy which allows the machine to function smoothly.

- Designed in compatibility with industrial standards.

- Timer functions which provide results accuracy.

- Specific temperatures can be set for testing.

- Transparent Canopy for see inside process.

Know About Our Products

Get to know our Laboratory Testing Equipment, designed with precision and excellence to meet the highest industry standards. Each product in our range is crafted to offer superior performance, durability, and innovation, ensuring they meet the diverse needs of our customers.

The Salt Spray Test assesses the corrosion resistance of metals and coatings by exposing them to a controlled salt fog environment. Crucial for industries like automotive, aerospace, and marine, it helps manufacturers evaluate the durability and longevity of their products under harsh conditions

Salt Spray Testing is a widely used corrosion testing method that simulates the effects of a corrosive environment on materials. By exposing test samples to a dense salt mist in a controlled chamber, this method assesses the resilience and longevity of coatings and metals. Crucial for industries like automotive, aerospace, and marine, it ensures material durability, reduces maintenance costs, and guarantees safety by predicting how materials will perform under harsh environmental conditions.

Salt Spray Testing is a widely used corrosion testing method that simulates the effects of a corrosive environment on materials. By exposing test samples to a dense salt mist in a controlled chamber, this method assesses the resilience and longevity of coatings and metals. Crucial for industries like automotive, aerospace, and marine, it ensures material durability, reduces maintenance costs, and guarantees safety by predicting how materials will perform under harsh environmental conditions.

The following parts can be salt spray tested.

- ED coating parts

- Painted Parts

- Phosphate Parts

- Powder Coating Parts

- Zinc Plating and Zinc Alloy Platings

The Salt Spray Test Chamber plays a critical role in product development and quality assurance. By simulating harsh environmental conditions, it helps in: Enhancing Product Durability: Identifying and mitigating potential weaknesses in materials and coatings. Meeting Industry Standards: Ensuring products comply with international standards for corrosion resistance. Improving Customer Satisfaction: Delivering reliable and long-lasting products to end-users.

Contact Form

Connect with us will help you with their queries...

For accurate laboratory testing results? contact us

for high-quality testing equipment solutions.