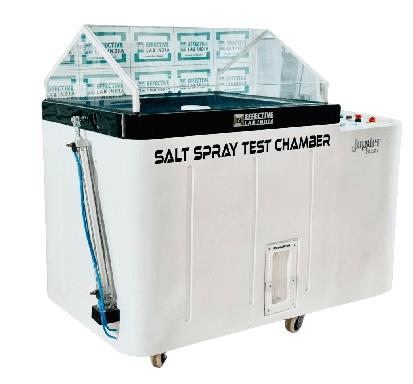

Salt Spray Test Chamber

Effective Lab India, we are one of the leading Salt Spray Test Chamber manufacturers and suppliers in India. Salt Spray Test Chamber also known as a salt “fog test chamber”. It is a very useful test in quality control, especially for the automotive, aerospace, and metal-finishing industries. These test chamber machines are used for evaluating various corrosion resistance of materials and surface coatings. It is one of the latest technological laboratory testing equipment that is capable of testing the corrosion resistant properties of materials with ease. This test chambers are designed as per the industry standard including ASTM B117 and JIS Z 2371. Our products are made of high-quality materials FRP so that its life can last for a long time. Basically, the main purpose of this Salt Spray Test Chamber is to determine and evaluate the resistance to corrosion. Its high corrosion resistance body provides long lasting life.

Salt Spray Test Chamber Suppliers

Effective Lab India salt spray chamber is a laboratory machine that simulates a harsh environment. Our Salt Spray Chamber is manufactured as per ASTM B117 and JIS 2371 standards. It is used to conduct Neutral Salt Spray Test (NSS Test) on metal surface coating. This instrument is used by manufacturers to test the corrosion process of metals after corrosion protection treatment such as painting and coating, lubrication in rust-resistant environments. Effective Lab India is a rising name in the field of test chamber which is a successful manufacturing company for its best-selling products in the Indian market. This Salt Spray Test Chamber quickly creates a salt-filled environment in which the quality of samples is tested. It has been specially designed to assess the changes in behavior of a metal when it comes in contact with moist and rusting environment and to evaluate its anti-corrosion capability. Our machines are constructed from corrosion resistant materials like Fiber Reinforced Plastic (FRP) which can give long term use. Our salt spray chambers come with sample-holding fixtures to make it easier to hang or place the samples.

Built to Withstand, Tested to Last

Ensure long-lasting protection with our Salt Spray Test Chamber, delivering reliable corrosion resistance

What is a Salt Spray Test Chamber?

A Salt spray chamber is a special type of corrosion testing machine that creates a corrosive environment in a short time, in which we can evaluate the resistance of the coating to the surface of our samples. This type of salt spray experiment or test involves spraying a salty solution 95% DM water and 5% NACL on the samples, which exposes it to a condition mimicking prolonged exposure to salty water and highly humid environments. A particular objective of this testing is to evaluate how samples such as metals and product coatings protect themselves against corrosion over time and for how long they can last.

How to Perform Salt Spray Chamber Corrosion Testing?

Our SST Chamber is one of the most trusted instruments for assessing the corrosion resistance of metals and other nanomaterial coating surfaces in salt laden environments. Below are some instructions on how you can perform corrosion tests using our salt spray chamber:

- Initial Preparation: First of all start preparing the test samples as per the specific requirements of your industry. First, you must ensure that the test sample is clean and free from any other contaminants.

- Organizing the samples: Place the samples carefully inside the chamber so that they do not fall during the test and also ensure that the cross contamination does not touch each other or the walls of the chamber.

- Test Parameter Setting: Program your chamber with required parameters such as temperature, humidity and test time. These parameters are very important for the testing process and must be set as per the standards you are following.

- Starting the Test: The simplest method to start the test is given in our machine, this feature is available in both our digital and HMI touch screen. For this, you first have to click the START button in our machine, which will start the test. Once the test begins, the chamber will begin spraying a fine salt mist onto the sample, to simulating a corrosion environment.

- Monitoring: You can monitor the progress of your test through your computer window, mobile display and machine digital display for observation. You must ensure that the chamber maintains a consistent condition throughout the test.

- Post-Test Analysis: Once the test is over, remove the sample and observe the effect of corrosion signs on the samples. It is mandatory to document the test procedures of samples for quality control and product development purposes.

Why Choose Effective Lab India Salt Spray Chamber?

According to the our expert engineers, our chamber is equipped with a user-friendly PID controller system through which the user operating the chamber can easily adjust the temperature inside the chamber which is from Ambient to +40 °c. Our salt fog test chamber comes with an HMI equipped touch screen display which plays an important role in facilitating the observation of corrosion inhibitors of different types of samples. To enhance the accuracy of the machine, a special zero-corrosion Pt 100 sensor is fitted in the equipment. Our Salt Spray Testing Chamber makes it easy for the manufacturing company to perform an accurate salt spray testing procedure with highly accurate results. The salt spray chamber ensures accurate, valid and reliable results.

It has special features such as glass wool insulation triple wall design which makes it capable of producing even stronger results and it meets international compliance standards. This salt spray test chamber brings cutting-edge technology to the industry and includes an air regulator that effectively and efficiently manages the effects of 0 to 30 psi air flow within the chamber. The salt spray tester is designed keeping in mind the internal testing standards which include appropriate standards such as ASTM B 117 and JISZ 2371. It also has the facility of automatic air purging and outside fog collection which makes it a special testing device which makes it easy for the user to perform error free testing.

What is the Salt Spray Chamber Price in India?

The price of a salt spray chamber varies depending on its features, size and specifications. The price of salt spray test chamber of all companies can be different depending on their specifications. Effective Lab India is one such manufacturing company in India which provides you a suitable and durable machine equipped with all types of new features in a low budget. The typical price of Salt Spray Test Chamber in India ranges from around ₹ 1.78 Lakh to ₹ 4.87 Lakh.

Conclusion

Salt spray test machine is an important lab equipment to ensure the stability, quality, and reliability of products in many industries. Effective Lab is one of the leading salt spray chamber manufacturers in India with its modern technology, specifications, and customer-focus perspectives. Are you looking for a salt spray chamber machine for your company's product testing which is available at a low price? Effective Lab India is the best option for you. Contact us today for sample testing on this no. +91 9555515525 or email info@effectivelabindia.com.

| Chamber Temperature Range | Ambient to 40°C |

|---|---|

| Power | 220V, Single phase, 50Hz, 15 A |

| Test Air Pressure | 0.7kg/cm²-1.2kg/cm² |

| Test Chamber Temperature Range | 35°C ± 2°C |

| Chamber Temperature List Count | 0.1°C |

| Temperature Control | Inbuilt PID Temperature Controller |

| pH value of Salt Solution | 6.5 to 7.2 pH |

| Air Saturator Temperature Least Count | 0.1ºC |

| Air Saturator Temperature Repeatability | ± 2ºC |

| Available Size | Models |

| 1 | Digital - 250 |

| 2 | Digital - 450 |

| 3 | Digital - 1000 |

| Inner Dimensions (mm) | Outer Dimensions (mm) |

| 780X620X720 | 1540x1070x1300 |

| 950x700x720 | 1800x1250x1250 |

| 1500x960x710 | 2370x1400x1350 |

- Various grades of metal can be easily tested.

- For an effective mode of operation, digital controls are provided.

- The results of testing are highly accurate.

- It is structured with strong rigged material for effective testing.

- Data management is easy which allows the machine to function smoothly.

- Designed in compatibility with industrial standards.

- Timer functions which provide results accuracy.

- Specific temperatures can be set for testing.

- Transparent Canopy for see inside process.

Know About Our Products

Get to know our Laboratory Testing Equipment, designed with precision and excellence to meet the highest industry standards. Each product in our range is crafted to offer superior performance, durability, and innovation, ensuring they meet the diverse needs of our customers.

The Salt Spray Test assesses the corrosion resistance of metals and coatings by exposing them to a controlled salt fog environment. Crucial for industries like automotive, aerospace, and marine, it helps manufacturers evaluate the durability and longevity of their products under harsh conditions

Salt Spray Testing is a widely used corrosion testing method that simulates the effects of a corrosive environment on materials. By exposing test samples to a dense salt mist in a controlled chamber, this method assesses the resilience and longevity of coatings and metals. Crucial for industries like automotive, aerospace, and marine, it ensures material durability, reduces maintenance costs, and guarantees safety by predicting how materials will perform under harsh environmental conditions.

Salt Spray Testing is a widely used corrosion testing method that simulates the effects of a corrosive environment on materials. By exposing test samples to a dense salt mist in a controlled chamber, this method assesses the resilience and longevity of coatings and metals. Crucial for industries like automotive, aerospace, and marine, it ensures material durability, reduces maintenance costs, and guarantees safety by predicting how materials will perform under harsh environmental conditions.

The following parts can be salt spray tested.

- ED coating parts

- Painted Parts

- Phosphate Parts

- Powder Coating Parts

- Zinc Plating and Zinc Alloy Platings

The Salt Spray Test Chamber plays a critical role in product development and quality assurance. By simulating harsh environmental conditions, it helps in:

- Enhancing Product Durability: Identifying and mitigating potential weaknesses in materials and coatings.

- Meeting Industry Standards: Ensuring products comply with international standards for corrosion resistance.

- Improving Customer Satisfaction: Delivering reliable and long-lasting products to end-users.

Contact Form

Connect with us will help you with their queries...

For accurate laboratory testing results? contact us

for high-quality testing equipment solutions.